If you’re hesitant to use the expander ball in your sizing die, you’re not alone. Many reloaders worry about pulling necks off-center or overworking their brass—leading them to add a separate mandrel step just to open the case necks.

A Smarter Expander Design

But there’s a better way—and Forster figured it out years ago.

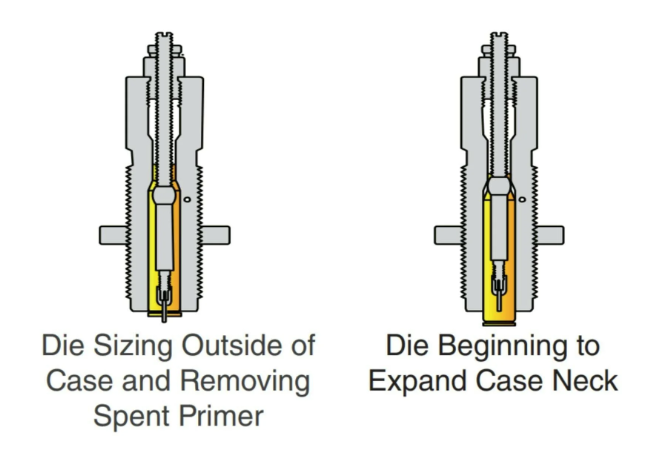

Unlike most sizing dies that position the expander ball near the decapping pin, Forster places the expander much higher in the die. Why? Because this keeps your case neck fully supported by the die as the expander is being removed.

Due to this advanced design, precise die setup becomes especially important to ensure optimal results. We recommend watching this video or reviewing your instructions for guidance.

Precision Options That Fit Your Load

Forster offers a wide selection of Oversized Expanders and can manufacture custom undersized expanders in precise .0005” increments—allowing you to achieve your ideal neck tension in a single pull of the handle. When paired with our Custom Neck Honing Service, you can significantly reduce the risk of overworking your brass.

If you have any questions about choosing the right expander or setting up your die, our team is here to help—don’t hesitate to contact us.