- Description

- Compatible With Caliber(s)

- Resources

In terms of improved accuracy, no single reloading function provides a greater return on your time than turning eccentric case necks to a consistent wall thickness. At the point of ignition, your brass must expand to allow bullet release. If the brass is thicker on one side of the case than the other, the thin side releases the bullet first and causes a slight bullet-to-bore misalignment that can seriously impair accuracy.

- The industry’s only carbide neck thickness cutter – no sharpening required.

- Precision machined with special angles and reliefs designed specifically for neck turning; cutter approach angle allows turning right up to the case shoulder.

- Micrometer adjustment knob allows fine adjustments in either direction; easily adjustable to .0005″. Index marks at increments of .001″ are clearly stamped on the tool body.

- Dedicated Pilots are sold separately, .002″ to .0025″ smaller than the bullet diameter.

The standard Case Holder (vise) included with HOT100 is designed for cases up to .592″. The Large Case Holder is required for rims that are .593″ to .812″ in diameter.

Do not confuse this standalone Hand-held Outside Neck Turner with the Outside Neck Turner Case Trimmer accessory.

[expand title=”Replacement Parts” swaptitle=” “]

Replacement Parts

[/expand]

You Might Also be interested in

Case Trimmer and Inspector Pilot – #31

Original price was: $8.00.$6.00Current price is: $6.00.

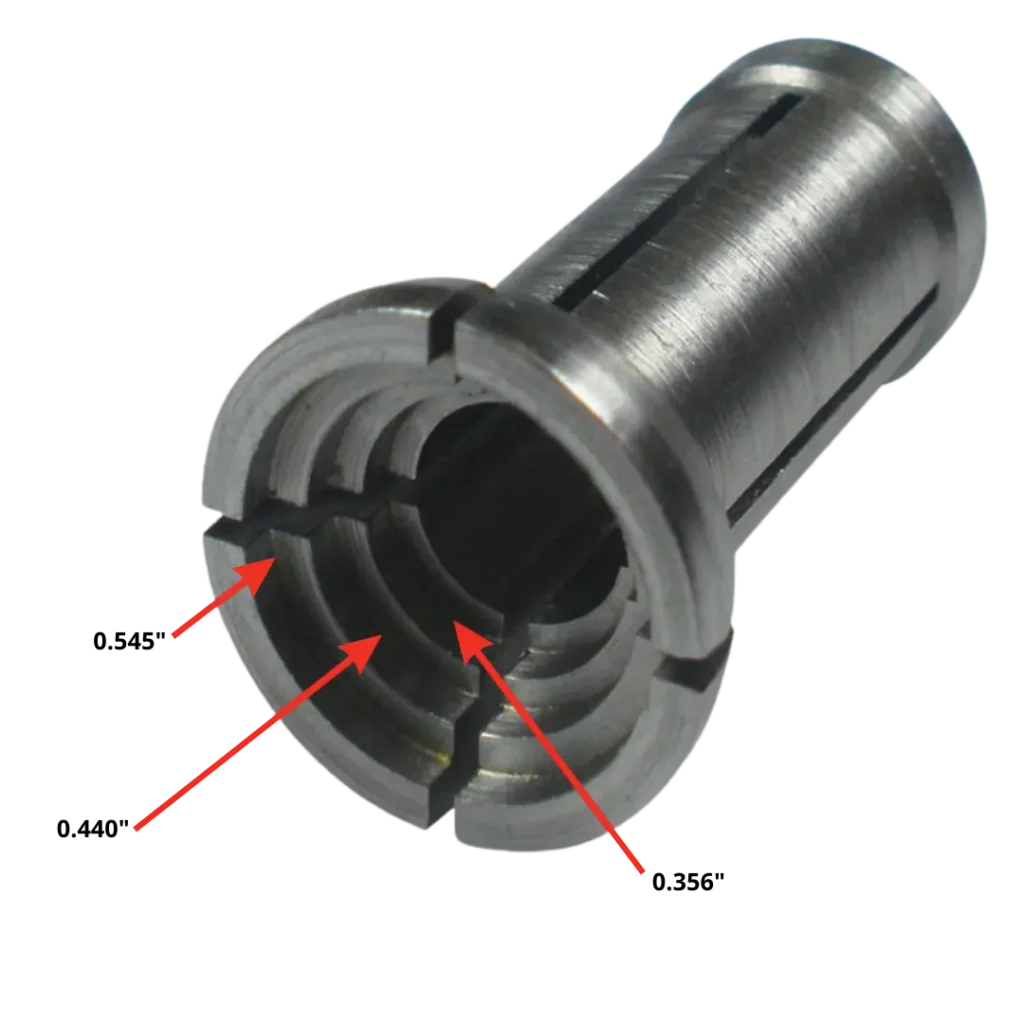

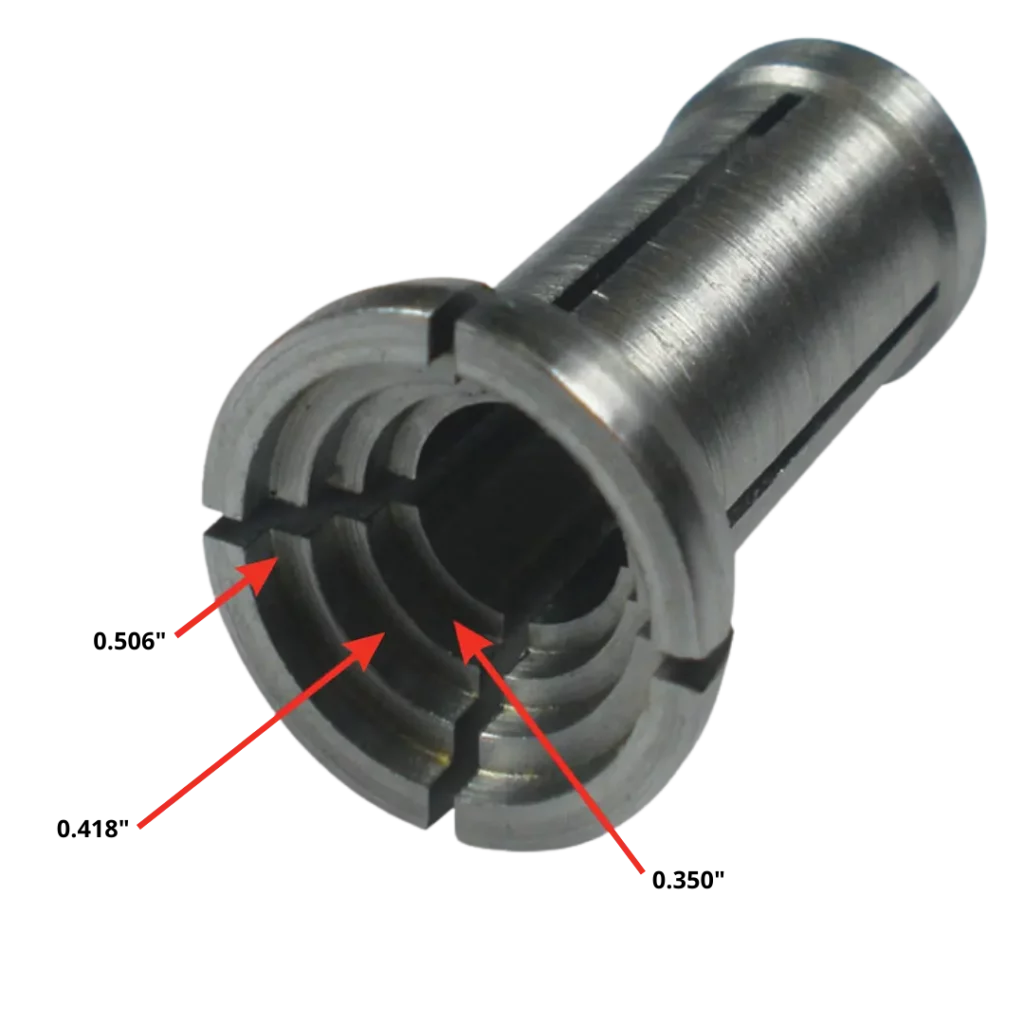

Classic Case Trimmer Collet – #8

Original price was: $20.00.$15.00Current price is: $15.00.

Case Trimmer Collet – #3

Original price was: $20.00.$15.00Current price is: $15.00.

Case Trimmer Collet – #2

Original price was: $20.00.$15.00Current price is: $15.00.