Barrel fluting is one of those upgrades that looks great and can cut some weight — but there’s more to know before committing.

What is barrel fluting?

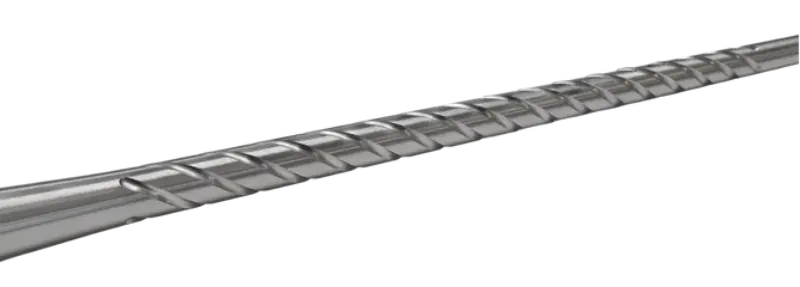

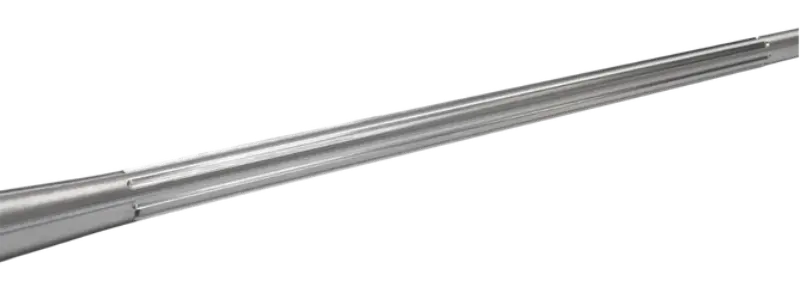

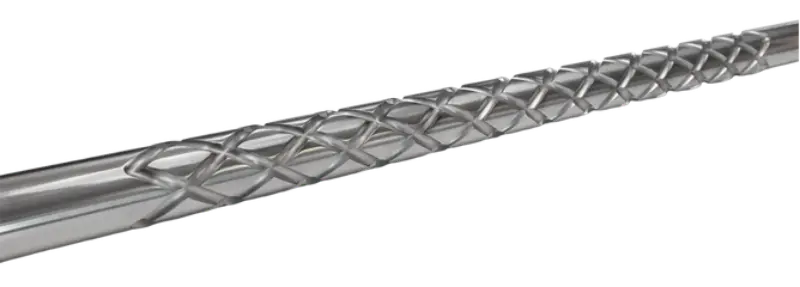

Barrel fluting is the process of cutting grooves into the barrel with a milling machine using an end mill or convex cutter. Styles range from multiple straight grooves to spirals, X-patterns, and custom shapes (for example, a series of small hexagons). Fluting can be purely decorative, but its most common functional reason is to reduce barrel weight.

What does it actually do?

- Weight Reduction: The primary, practical benefit is lighter weight without changing barrel length.

- Appearance: Fluting offers a striking custom look.

- Cooling Claims: Some say fluting helps cooling; that has not been proven and shouldn’t be the main reason to flute a barrel.

Does fluting affect accuracy?

If fluting is performed correctly and within the barrel manufacturer’s recommended flute depth, we have not seen a negative effect on accuracy. Many major barrel makers recommend a maximum flute depth of 0.100″ (and often less on smaller profiles); exceeding that depth may void warranties or carry disclaimers. Overly deep cuts or introducing heat/stress in the bore area can change barrel harmonics — which means an existing load that shot great may need re-tuning afterward.

In fact, one barrel we fluted after it had already been chambered retained full accuracy — that same barrel went on to win the 2025 Wisconsin PRS finale and season.

Build Your Dream Rifle

Here at Forster, we’ve launched a full-service gunsmithing operation through Iron Door Guns, offering custom rifle chambering paired with precision fluting options. Stop by or give us a call to start building your dream rifle.